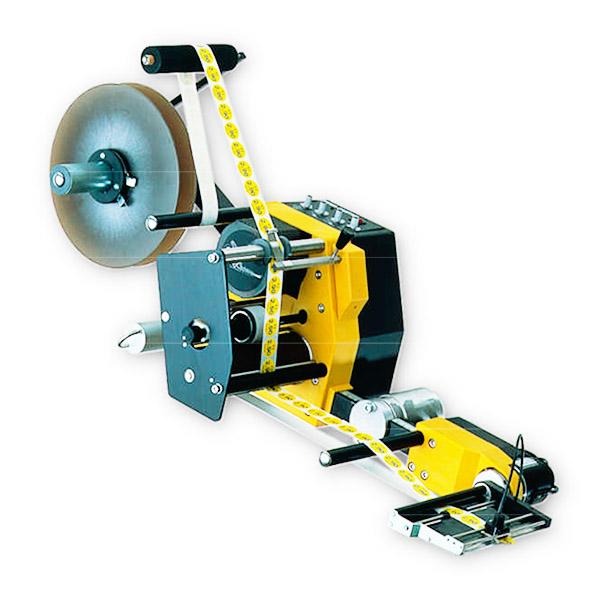

Videojet 6330 Thermal Transfer Overprinter

Purpose and equipment

The Videojet DataFlex® 6330 is built to withstand tough production line environments. Designed for simple maintenance with minimal wear parts and easy-to-change ribbon to give an overall more

productive operation.

Delivery

information

Delivery options: ✔ Customer pick-up ✔ Road transport ✔ Rail transport ✔ Air transport ✔ Sea transport

Warranty

information

✔ Warranty and post-warranty services ✔ Prompt maintenance services ✔

Consultations on equipment options, equipment diagnostics, equipment

troubleshooting, settings ✔ Commissioning and start-up ✔Customer

personnel training ✔ Equipment trial testing ✔ Spare parts, wear parts

and components delivery

Specifications

Width / resolution

32 mm or 53mm 300 dpi (12 dots/mm)

Print Area, mm

32mm intermittent printing mode: 1.3” (32mm) wide x 3.0” (75mm) long 32mm continuous printing mode: 1.3” (32mm) wide x 7.9” (200mm) long 53mm intermittent printing mode: 2.1” (53mm) wide x 3.0” (75mm) long 53mm continuous printing mode: 2.1” (53mm) wide x 7.9” (200mm) long

Print Speed, mm/sec

29.5 in./sec (750mm/sec)

Ribbon length

700, 1200

Working temperature, °С

32°-104°F (0°- 40° C)

Air pressure, no more, atm

Not necessary

Power supply

100-240VAC

External Communications

RS232, dual Ethernet, USB memory stick and scanner support, Binary and ASCII comms protocols, Windows® drivers, ZPL and SATO emulations

Remote Coder Configuration Software

CLARiSOFT™

- Reduce costs and downtime, maximize printhead life and gain consistent print quality thanks to airless Videojet Intelligent Motion™ technology.

- Simple change ribbon cassette, with pushbutton lock mechanism, allows for fast and easy ribbon replacement.

- Offers high-quality codes up to speeds of 250 packs / minute

- Up to 1,200m ribbon capacity and a variety of ribbon economy modes help maximize the time between ribbon changeovers

- Compact design easily integrates into most production lines

- Using default settings you can maintain consistent code quality and avoid conventional air and energy settings that operators might over-adjust

- Quickly discover code legibility issues that indicate the potential need for printer maintenance

- Industry-leading simple cassette change designed for fast ribbon replacement to maximize uptime

- 25% faster throughput than previous Videojet TTO models

- Simple operator interface

- Minimal wear parts are easy to change out, improving production line uptime

Recommended:

If you have any questions - contact us!